When you have a question and don't know the answer we tend to search the internet.

You might just find the answer to get the cogs turning and come up with a bright idea.

These pages contain answers to question regarding automatic gate motors and automatic gate setup.

You might just find the answer to get the cogs turning and come up with a bright idea.

These pages contain answers to question regarding automatic gate motors and automatic gate setup.

DIY - AUTOMATIC SLIDING GATE

Want to install your own automatic sliding gate. No problem. Automatic Solutions has all the gear your need to build and install an automatic sliding driveway gate. You don't even have to make the gate if you choose. We have a range of ready made sliding driveway gates at a prices so low you will probably pay more just for the material and components. We also supply flat pack gates cut to size or custom made to your design.

Note: The information on this page is intended as a guide only representing a typical installation. Dimensions will vary dependent on your gate type and running gear setup.

ON THIS PAGE

Planning and preparation

Mounting your motor and rack

Gate stops

Ready to power and program.

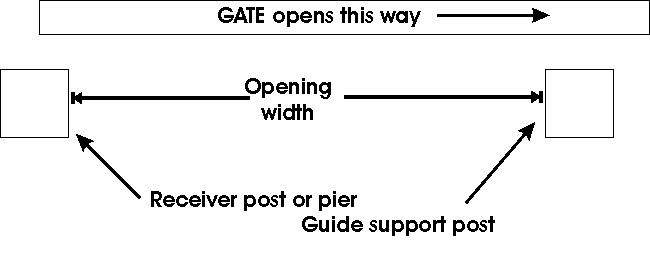

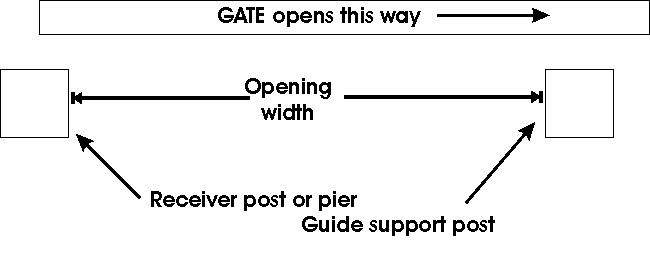

Planning and preparation. The more time you spend at this stage the less mistakes made and time wasted doing re-work, so spend a bit of time getting this part right. Any sliding gate has only a few key parts that need consideration - the track, the gate, guide support post or pier, receiver post or pier. Granted, the automation section has many more considerations but just for the moment let's concentrate our planning on the basics as they remain constant whether the gate is automated or not.

The first thing you need is two definable points to determine your gate opening. You may have existing posts, brick or concrete piers. If not you will need to allow for the installation of posts or piers to act as as a receiver on closing and guide support.

If you are installing new posts I would suggest 75mm square as a good size and if concreting into the ground a minimum of 600mm in concrete with legs attached. (See section on post installation).

Once you have determined your two points you can start to look for and record some information - 1. The opening width between our two posts or piers. 2. This will give you a width for your gate - usually this is the opening width plus 50mm overlap on the receiver side plus overlap on the guide / roller side, typically 100mm for a manual gate or 400mm for an automated gate. 3. Once you have a total gate width you can check to ensure sufficient room to slide open fully without impeding the opening.

Your Automatic Solutions branch will help you choose tracks, motors etc. and advise dimensions required. You can also e-mail us here for help and upload photos if you have them.

Now that you have worked out where your gate will slide you can determine your track style. In general there are two main variations of track, "bolt down" and "concrete in", but it is fair to say that there are many different variations particularly in the concrete in style. When considering your track type simply remember that the track centre will run 100mm from the inside edge of your posts or piers when using a 50mm thick gate. When your gate is thicker than this you will need to adjust the track centre to suit. To view track styles click here.

Mounting your motor and rack. The most common method of motor mounting is to bolt down to a pre prepared concrete pad although most motors have a base plate available that can be installed in concrete beforehand with your track work making the bolt down procedure even simpler. Use a length of rack to position your motor in relation to the gate and take into account limit switch positioning.

Once you have bolted the motor down securely use your manual override to put the gate into manual mode. Start at one end and use tek screws to fasten your first length of rack centred over the pinion. The rack should not sit directly on the pinion but have a 1mm gap between the pinion and the rack. Slide the gate back and forth to ensure the first length is level. You can now slide the gate along until the pinion is about 800mm from the end of the first length of rack. Attach the next length of rack into the interlocking point of the first length of rack and position the other end of the rack on the pinion. You should now be able to fasten this length of rack at two points and move along to the next and subsequent lengths. You may need to cut the last length to suit. When all lengths are fitted check the operation of the rack before inserting all fasteners.

Gate Stops. All automatic gates require opening and closing stops for safety and programming. On sliding gates this means a good secure opening stop and a gate receiver normally takes care of the closing stop. Put in good mechanical stops and save the maintenance and frustration.

Ready to power and program. At this point I assume you have had your power professionally connected and all other wiring has been completed. My simple suggestion here is that you leave most extras like photo cell beams and keypads not connected, and have all required loops installed until after you finish programming and have your gate running smoothly. Having bells and whistles connected will only complicate matters if things don't go exactly as expected. By having the bare basics makes fault finding much easier.

ON THIS PAGE

Planning and preparation

Mounting your motor and rack

Gate stops

Ready to power and program.

Planning and preparation. The more time you spend at this stage the less mistakes made and time wasted doing re-work, so spend a bit of time getting this part right. Any sliding gate has only a few key parts that need consideration - the track, the gate, guide support post or pier, receiver post or pier. Granted, the automation section has many more considerations but just for the moment let's concentrate our planning on the basics as they remain constant whether the gate is automated or not.

The first thing you need is two definable points to determine your gate opening. You may have existing posts, brick or concrete piers. If not you will need to allow for the installation of posts or piers to act as as a receiver on closing and guide support.

If you are installing new posts I would suggest 75mm square as a good size and if concreting into the ground a minimum of 600mm in concrete with legs attached. (See section on post installation).

Once you have determined your two points you can start to look for and record some information - 1. The opening width between our two posts or piers. 2. This will give you a width for your gate - usually this is the opening width plus 50mm overlap on the receiver side plus overlap on the guide / roller side, typically 100mm for a manual gate or 400mm for an automated gate. 3. Once you have a total gate width you can check to ensure sufficient room to slide open fully without impeding the opening.

Your Automatic Solutions branch will help you choose tracks, motors etc. and advise dimensions required. You can also e-mail us here for help and upload photos if you have them.

Now that you have worked out where your gate will slide you can determine your track style. In general there are two main variations of track, "bolt down" and "concrete in", but it is fair to say that there are many different variations particularly in the concrete in style. When considering your track type simply remember that the track centre will run 100mm from the inside edge of your posts or piers when using a 50mm thick gate. When your gate is thicker than this you will need to adjust the track centre to suit. To view track styles click here.

Mounting your motor and rack. The most common method of motor mounting is to bolt down to a pre prepared concrete pad although most motors have a base plate available that can be installed in concrete beforehand with your track work making the bolt down procedure even simpler. Use a length of rack to position your motor in relation to the gate and take into account limit switch positioning.

Once you have bolted the motor down securely use your manual override to put the gate into manual mode. Start at one end and use tek screws to fasten your first length of rack centred over the pinion. The rack should not sit directly on the pinion but have a 1mm gap between the pinion and the rack. Slide the gate back and forth to ensure the first length is level. You can now slide the gate along until the pinion is about 800mm from the end of the first length of rack. Attach the next length of rack into the interlocking point of the first length of rack and position the other end of the rack on the pinion. You should now be able to fasten this length of rack at two points and move along to the next and subsequent lengths. You may need to cut the last length to suit. When all lengths are fitted check the operation of the rack before inserting all fasteners.

Gate Stops. All automatic gates require opening and closing stops for safety and programming. On sliding gates this means a good secure opening stop and a gate receiver normally takes care of the closing stop. Put in good mechanical stops and save the maintenance and frustration.

Ready to power and program. At this point I assume you have had your power professionally connected and all other wiring has been completed. My simple suggestion here is that you leave most extras like photo cell beams and keypads not connected, and have all required loops installed until after you finish programming and have your gate running smoothly. Having bells and whistles connected will only complicate matters if things don't go exactly as expected. By having the bare basics makes fault finding much easier.